New U.S. Solar Factories Move Forward

By Christian Roselund

During November 2022 three PV manufacturers made major announcements related to expansions of PV cell and module production in the United States. This includes plans by 3Sun and Philadelphia Solar for at least 4.2 gigawatts of new crystalline silicon module manufacturing capacity in 2025, as well as First Solar revealing the location of its new 3.5-gigawatt thin film factory in the U.S. Southeast.

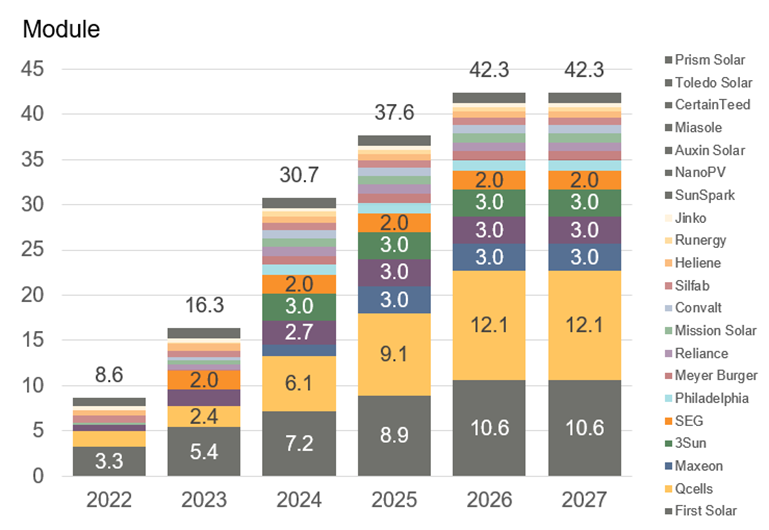

These are some of the first multi-gigawatt announcements made following the passage of the Inflation Reduction Act, which includes substantial incentives for domestic production of polysilicon, wafers, cells, modules, and PV materials. With these announcements, other announcements, and plans that have been revealed in the media, CEA is now tracking 25.6 gigawatts of cell capacity and 42.3 gigawatts of module capacity, up from 3.3 gigawatts of cell (all of which is First Solar’s integrated thin film production) and 8.6 gigawatts of module assembly in 2022.

Polysilicon, ingot and wafer announcements are much more limited; the only new polysilicon capacity announced is the re-starting of REC Silicon’s Moses Lake facility. For ingot and wafer, two new projects are anticipated: Hanwha Q Cells’ plans for a 9-gigawatt integrated ingot, wafer, cell, and module facility, and a 3-gigawatt plant planned by SPI Energy

Philadelphia Solar

The first large announcement came from Jordanian module maker Philadelphia Solar, which has joined forces with newly formed U.S. entity Translucent Energy to manufacture PV modules in the United States. Philadelphia says that it is on track to complete a 1.2-gigawatt factory to produce modules using monocrystalline passivated emitter and rear cell (PERC) cells by Q4 2024. The company says that it will then transition to production of modules using heterojunction silicon cells in 2025.

Philadelphia has been suggesting that it will build a U.S. factory for months, and this announcement is the first definitive move. The module maker has not said where this factory will be located.

Philadelphia Solar does bring experience as the largest PV module manufacturer in the Middle East and North Africa region with a production capacity of 580 megawatts per year. Philadelphia has also suggested that it has a captive supply chain to serve this plant. The company’s press release contains the cryptic statement: “the alliance oversees module production from silicon to ingots, bricks, wafers, and cells, providing exceptional quality PV modules.”

Enel / 3Sun

Ten days after Philadelphia Solar’s announcement, Enel North America announced plans to build a cell and module factory in the United States with the capacity to make “at least” 3 gigawatts of bifacial heterojunction PV modules by 2025. While it still evaluating sites for the factory, Enel expects to start construction in the first half of 2023.

Like Philadelphia Solar, Enel comes with experience through its 3Sun facility in Catania, Italy, which it is currently expanding from 200 megawatts to 3 gigawatts. The company also has the benefit of a captive pipeline to sell its products into, given Enel’s substantial presence in the U.S. market as a wind and solar developer.

Enel plans to eventually scale the factory to 6 gigawatts annually. It is not clear from the company’s announcement if the volume of cells made will match the module production volume. However, this will still be the first commercial-scale crystalline silicon cell factory in the United States following the shut-down of Suniva’s facilities in 2017.

First Solar

Of all the announcements in November, First Solar is the closest to building a factory. The module maker has revealed that the 3.5 gigawatt thin-film factory it has been planning for months will be in an industrial park in Lawrence County, Alabama. The facility will make First Solar’s massive Series 7 module, which at 2.794 square meters is even larger than its Series 6.

The factory will represent a $1.1 billion investment. Like Philadelphia Solar and Enel, the company plans to commission its factory by 2025. First Solar has many factories in Malaysia and Vietnam, but this will be the company’s first U.S. module factory outside the state of Ohio. First Solar is currently building a third factory in Ohio which it expects to come online in the first half of 2023. When the Alabama facility and the one in Ohio are online, First Solar expects to have the capacity to make 10.7 gigawatts of PV modules in the United States each year. This is more than the aggregate capacity of all U.S. module makers in 2022.

First Solar is additionally investing $270 million in a new research and development facility in Ohio, to support its manufacturing.

The thin-film maker clearly has near-term demand for the output of its new factories. The company is sold out to 2025, and recently announced a deal with Intersect Power to provide 4.9 gigawatts of PV modules for the period 2025 through 2029.

IRA and Factory Expansions

Both First Solar and Enel explicitly cited the Inflation Reduction Act (IRA) as a support for U.S. manufacturing moves. The law provides a $0.07 per watt tax credit to produce PV modules in the United States, and a $0.04 per watt credit for cells. First Solar will be able to claim both of these. Additionally, CEA’s research indicates that First Solar will be able to claim the $12 per square meter wafer credit for its photon absorber layer.

In the following months, CEA will be tracking the progress of these factories and other manufacturing announcements. There are factors that can both reduce and expand the amount of manufacturing capacity that will ultimately be online by any given year. Chiefly, there are many challenges to completing factories on time, but we expect that as some factories are delayed or even cancelled other new announcements will be made.

Press release: Joint Venture Brings a New Source of Tier-1 Solar Photovoltaic Modules to the U.S. Market (Philadelphia Solar)

Press release: Enel announces intentions to build solar PV cell & panel manufacturing facility in U.S. (Enel)

Press release: First Solar Selects Alabama for Fourth American Manufacturing Facility (First Solar)