Renewables to Reduce Texas’ Wholesale Power Cost by $11 Billion in 2022

By Christian Roselund

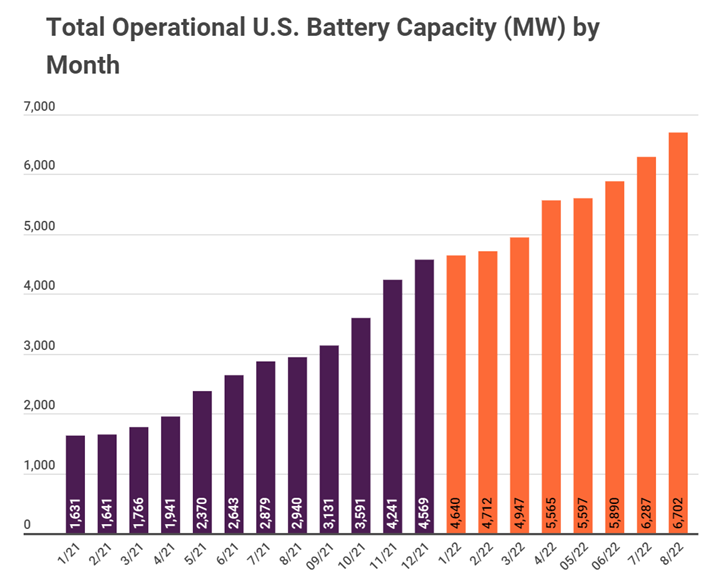

A new analysis by energy economist Dr. Joshua Rhodes indicates that renewable energy has already reduced wholesale electricity costs in Texas’ grid by roughly $7.4 billion and are on track to reduce costs by more than $11 billion over the full year 2022. This is a savings of $380 for every resident of the state. Rhodes’ analysis has further found that widespread adoption of renewables has reduced wholesale electric costs by $27.8 billion between 2010 and August 2022 in the Electric Reliability Council of Texas (ERCOT) grid.

Rhodes’ analysis finds that as renewables have scaled, these savings have increased, with an effect on wholesale electricity prices of $1.17 per megawatt-hour (MWh) in 2012 but a $20.60/MWh benefit expected in 2022. The report notes that some of the outsized savings in 2022 come from the ability of renewables to provide a price hedge against natural gas and coal prices, both of which are much higher in Texas in 2022 than in previous years.

But wind and solar aren’t like other hedges. As noted by Rhodes, by bidding into wholesale power markets at zero or close to zero prices, wind and solar consistently suppress wholesale power prices. Rhodes notes that average market prices are around $72/MWh in ERCOT so far in 2022 and its analysis implies that prices would have been around $90/MWh without the suppressing effect of wind and solar. These prices are higher than in previous years, and much of the recent increase in both the actual and reference prices are due to higher natural gas prices, which have nearly doubled from $3.64 per million British thermal units (MMBtu) in 2021 to $6.24/MMBtu in 2022.

In addition to the raw electricity cost savings, Rhodes’ report also documents substantial savings in cooling water, sulfur oxides (SOx), nitrogen oxides (NOx), and CO2 as a result of the replacement of fossil fuel generation with wind and solar.

Source: The Impact of Renewables in ERCOT (IdeaSmiths)